Sale and processing of intermediate products: Do all steps have to be documented?

EUDR - Reading time: 8 Min

The EU regulation against deforestation (EUDR) presents companies with new challenges - especially when raw materials are not traded directly as end products but are processed into intermediate products beforehand. Whether cocoa mass, flour, chipboard or vegetable oil: the EUDR also requires complete traceability back to the origin of the raw materials used at these stages of the value chain. But what exactly does this mean in practice? Which processing steps must be documented? And when does a new due diligence obligation begin? This article provides a comprehensive overview of how companies can deal with intermediate products and bulk batches in accordance with the EUDR - practical, risk-oriented and with concrete recommendations for more legal certainty and efficiency.

The most important facts at a glance

Intermediate products are processed raw materials such as flour, cocoa mass or wooden boards that are produced before the end product and must remain traceable.

A new due diligence obligation always arises when a product is supplied to another company as part of a commercial activity and is therefore made available on the market. If the product has already been placed on the market in the EU, no new due diligence obligations arise - provided nothing has been changed to the product.

Each partial quantity of a collection batch must be clearly documented in terms of origin, parcel ID and quantity.

Detailed documentation of internal processing steps is only necessary in the event of mixing or increased risk.

Through digital systems, clear processes and risk-based documentation that make the origin and quantities traceable at all times.

Executive Summary

The EU regulation against deforestation (EUDR) sets clear requirements for the traceability of raw materials - even if they are processed into intermediate products. Companies must be able to prove exactly where the raw materials used come from for each relevant product, right down to the geographical area of origin. This obligation applies along the entire supply chain - from cultivation to processing to sale - if a product is placed on the market.

Collective batches and mixing processes in which raw materials from different sources are brought together require particular attention. Here, the composition, quantity ratios and origin of each partial quantity must be fully documented. A new EUDR due diligence declaration is generally not required if a product is merely passed on to another company within the EU - provided the product has already been properly placed on the market. Internal processing steps, on the other hand, do not trigger a new reporting obligation as long as traceability is maintained.

In practice, companies can use digital systems, barcoded storage units and automated logs to significantly simplify their documentation and at the same time reliably meet the requirements of the EUDR. A risk-based approach is permissible: The higher the risk - for example, in the case of products from high-risk areas or frequent mixing - the more detailed the documentation and assessment must be. It is crucial that the origin, processing and quantities are traceable at all times. This means that even complex supply chains can be efficiently mapped in compliance with the EUDR.

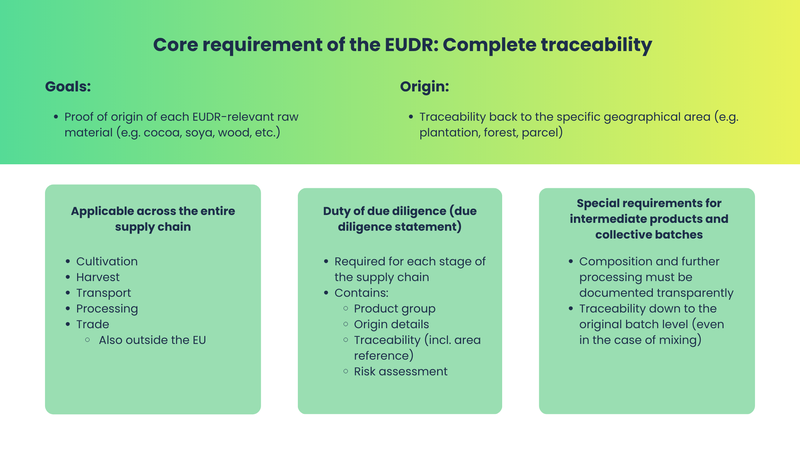

The EUDR basic requirement: Complete traceability

What does "full traceability" mean?

The EUDR (EU regulation against deforestation) requires companies to be able to prove exactly where the raw materials in certain products come from - this is what is meant by "full traceability". For every product covered by the regulation (for example cocoa, coffee, soy, palm oil, beef or wood), it must be clear from which farm, plantation or forest the raw materials originally came from. Traceability must be documented precisely, down to the geographical area, i.e. the place on the map where the raw materials were grown or harvested.

This traceability must apply throughout the entire supply chain: from cultivation to harvesting, transportation, processing and trade - whether inside or outside the EU. It is therefore not enough just to know who you bought the product from. You have to be able to trace it all the way back to the source.

A due diligence statement must be available for each stage of the supply chain, containing key information such as product group, origin, traceability and risk assessment. All intermediate steps must be documented so transparently that traceability is ensured down to area or parcel level. For intermediate products and collective batches in particular, this means that their composition and further processing can also be clearly documented.

Intermediate products are part of the supply chain

Processing raw materials into intermediate products is commonplace in many industries. For example, cocoa beans are processed into cocoa mass or butter, palm oil is split into fractions or wood assortments are transformed into semi-finished products (such as wooden boards, veneers or chipboard) before they are incorporated into the end product. From a legal perspective, intermediate products are an integral part of the supply chain. Legislation therefore also requires consistent proof of origin and processing for them. The following applies: processing stages that influence the end product (such as mixing, refining, portioning) do not trigger a new EUDR notification as long as the goods are still in the possession of an EU company and are not "placed on the market" or made available on the EU market again.

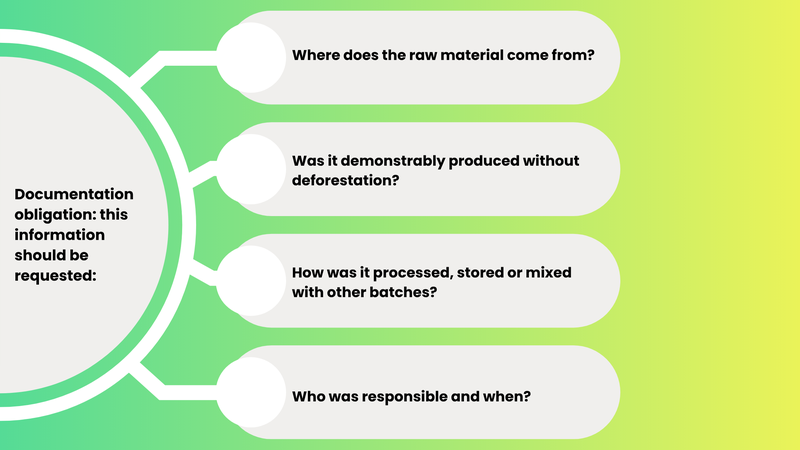

Documentation requirements for processing companies

What actually needs to be documented?

The question of what needs to be documented in detail for intermediate products or processed raw materials is best answered by looking at the objectives of the EUDR. The focus here is on an unbroken chain of relevant information:

- Where does the raw material come from?

- Was it demonstrably produced without deforestation?

- How was it processed, stored or mixed with other batches?

- Who was responsible and when?

For each intermediate product, it should therefore be documented exactly from which original batches it was produced. Clear batch identification, delivery documents and production records that reflect the number and type of raw materials used are generally sufficient. If several original batches are mixed, the exact (quantity-related) composition must be traceable. The challenge increases the more often collective batches or intermediate products from different sources of origin are formed, for example when processing large quantities of soy, cocoa nibs for chocolate production or sawmills that bundle logs from different parcels.

Particularly important and always required are details on the entry of contacts into the supply chain and the transfer of relevant information (parcel ID, proof of origin, freedom from deforestation). Companies that carry out further processing must document all plausible processing steps that are necessary for the consistency of the proof of origin and thus for EUDR-compliant traceability. Pure transportation or storage withdrawals without mixing or processing do not require separate documentation.

Practical tip: Documentation according to relevance and risk

In practice, a risk-based approach to documentation is recommended. Not every internal movement needs to be logged, as long as the origin and quantity relationship of primary materials remain secure and traceable. It is important to note that if a product has a known risk, for example because it originates from an area with a high risk of deforestation (high-risk country) or because the origin is difficult to trace (e.g. due to frequent mixing of different sources of origin), then particular care must be taken. In such cases, companies must provide more detailed documentation and assess the risk particularly carefully.

For example, a milling company that processes wheat from different countries of origin into flour can use clear labeling and digital tracking of input batches to ensure that all downstream production is correctly allocated. This can reduce risks during audits. At the same time, weak points in traceability can be better traced and the legal requirements of the EUDR for collective batches and intermediate products can be fulfilled in a compliant manner.

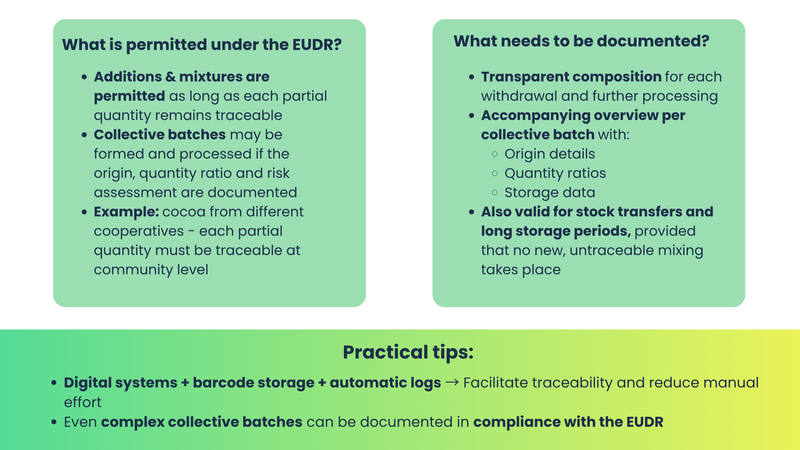

Handling collective batches and stock goods

The challenge of mixing

Especially when bundling large quantities of goods, whether soy, palm oil, coffee or wood, raw materials from different plantations or countries are brought together to form a so-called collective batch. These collective batches pose a particular challenge from the perspective of the EUDR, as precise traceability back to the origin must be guaranteed for each partial quantity. Here, practice often collides with the legal text: technically, the origins represented in a collective batch can extend over dozens, sometimes even hundreds of individual producers.

Nevertheless, the EUDR requires that each partial volume remains fully identifiable on an origin and quantity basis. Companies are therefore faced with the task of documenting the original batches from which the collective batch was formed at the time of receipt, each stock transfer and each processing operation. Digital warehouse management systems, detailed delivery bills and production records play a key role here. If further processing takes place later, for example grinding, extraction or portioning, the composition of the original data must be fundamentally retained.

What is permitted and what must be documented?

The EUDR permits additions and mixtures as long as traceability is guaranteed for each partial quantity of the collective batch. It is therefore still permitted to form collective batches and process them further if a transparent system ensures that the origin, quantity ratio and risk assessments are maintained. This is common in the cocoa sector, for example, where individual export batches come from several farmer cooperatives, but each partial batch can be documented back to the community of origin.

In storage practice, the following applies: Mixed items are EUDR-compliant if their origin can be precisely documented and the risk assessment explicitly addresses the mixing. This presupposes that the exact composition can be transparently traced for each removal and further processing (such as the drawing of partial quantities). Companies can fulfill this requirement by keeping an accompanying overview for each collective batch, which bundles all relevant origin, quantity and storage information. This should also be the case for longer storage periods and frequent stock transfers, as long as there is no subsequent mixing with new, untraceable quantities.

Practical experience from the grain and timber industry shows: When companies use barcoded storage units, digital booking systems and automatic production logs, traceability becomes much simpler and more transparent. The manual effort required for verification is significantly reduced. At the same time, even complex collective batches can be documented reliably and in compliance with EUDR.

Processing steps and "new placing on the market" - when does the obligation begin again?

When does an intermediate product become a new EUDR case?

One of the most common uncertainties with regard to EUDR traceability is when a separate EUDR notification is required for an intermediate product or a new processing step.

The core of the regulation is: If a product is made available through a change or is taken over by another market participant, a new due diligence declaration is required. It is important to note whether the product has been manufactured exclusively from products that have already been subject to due diligence. If this is the case, it is possible to refer to previous DDSs. However, this does not exempt from the responsibility for the conformity of the products.

Example: A company imports cocoa beans from outside the EU and processes them into cocoa liquor. Even if the cocoa mass remains in the possession of the same company within the EU, it is only used for its own needs and is not passed on to third parties, a DDS must be created.

As the first distributor on the Union market, the company must comply with the full due diligence obligation and submit a due diligence declaration with the geolocation data of the cocoa beans (HS 1801) in the information system.

For example, if the cocoa mass (HS 1803) is sold to a chocolate factory, the factory converts a relevant product into other relevant products and is therefore considered a downstream non-SME market participant for chocolate (HS 1806).

As a non-SME market participant, the chocolate factory must submit a due diligence declaration in the information system. Since the chocolate was produced using the cocoa beans already subject to due diligence (HS 1801), the factory can refer to the due diligence declaration submitted by the cocoa bean buyer, stating the corresponding reference number. However, it must first ensure that the upstream due diligence obligation in accordance with the EUDR has been fulfilled. The processor remains responsible for the conformity of the products concerned.

Transforming processing steps (e.g. grinding, refining, extracting, fractionating) without transfer of ownership do not in themselves trigger a new EUDR notification, but the provision to new legal entities does. In this case, the downstream obligation begins for the receiving company to ensure full EUDR traceability based on the origin data and quantities provided.

Exemplary processing chain

Suppose a Brazilian farmer delivers soybeans to a regional collection warehouse. Beans from 30 other farms are collected there and cleaned together. The exporter forms a collective batch from this, which is sent to the EU and documented via an EUDR declaration. An EU importer sells part of the collective batch to an oil mill that presses soybean oil. As long as the oil mill stores and processes the oil, it can rely on the documentation of the original collection batch.

If it passes the oil on to a food manufacturer, the latter in turn is obliged to submit a new EUDR declaration of compliance if it processes it into relevant products listed in Annex I EUDR. If the manufacturer uses the oil to produce margarine, for example, which is not listed in Annex I, it is not a relevant product under EUDR. As a result, the EUDR due diligence obligation would lapse in this case.

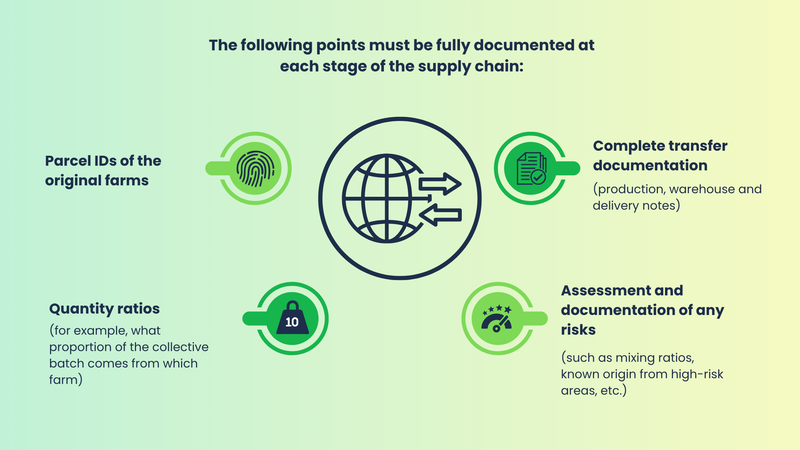

The following points must now be fully documented at each stage of the chain:

- Parcel IDs of the original farms

- Quantity ratios (e.g. what proportion of the collection batch comes from which farm)

- Complete transfer documentation (production, warehouse and delivery bills)

- Assessment and documentation of any risks (such as mixing ratios, known origin from high-risk areas, etc.)

At no point may the transparency of the origin of the respective partial quantity be lost, otherwise the end product loses its EUDR conformity. A non-compliant part of a product must be identified and separated from the rest before it is placed on the EU market or exported. This part may not be placed on the EU market or exported. If identification and separation is not possible because the products have been mixed with the rest, the entire product is non-compliant. It may not be placed on the EU market or exported.

Recommendations for action in practice

Establish clear processes and systems

The most important success factor for trouble-free documentation along complex supply chains lies in structured, clearly defined processes. Companies should record all relevant processing steps, ownership and quantity transfers as well as mixtures in a standardized system, for example using ERP systems with integrated traceability modules or software solutions such as the lawcode Suite. In larger organizations, a clear assignment of roles and responsibilities is recommended to ensure that all internal and external transfers are mapped in compliance with the EUDR.

The standardized recording and transfer of parcel IDs, proof of origin and processed quantities is also essential in order to ensure complete EUDR traceability within the shortest possible time, even in the event of inspections or audits. Companies that have so far mainly used paper-based documentation should consider switching to digital processes in order to improve efficiency, accuracy and legal certainty in the long term.

Managing interfaces - internally and externally

An often underestimated risk factor in EUDR documentation practice is interface management. Whenever material flows cross internal departmental, plant or site boundaries or change between different supply chain actors, the risk of information loss, transmission errors or ambiguities with regard to source data increases. Companies should ensure that all relevant interfaces are secured through consistent data transfers, clearly defined handover processes and regular control mechanisms.

Collaboration with external partners, for example in contract processing, warehousing or external transport, must also be designed in such a way that all relevant EUDR obligations are fulfilled seamlessly. It is advisable to contractually define which information obligations apply, e.g. with regard to the transmission of digital source data in the agreed format. The use of industry standards to ensure seamless traceability in practice should also be agreed in advance.

Allow risk-based documentation

The EUDR does not require a complete individual record of all internal steps; instead, a risk-based documentation approach can be chosen. This means that companies can rely on simplified documentation methods where the origin of the material remains clear and traceable without risk factors. Only when risk factors are added, such as repeated blending, additions from non-certified sources or processing from areas with an increased risk of deforestation, must the documentation be supplemented with additional evidence, protocols and risk assessments.

Practical experience, particularly from the cocoa and palm oil sectors, shows that risk-based documentation is not only legal, but also audit-proof, provided that internal company instructions, digital protocols and traceable risk assessments are used systematically. As a result, companies benefit from greater efficiency without breaching the EUDR collective batch and intermediate product regulations.

Conclusion and outlook

Even though the EUDR places high demands on traceability and documentation, this does not mean that every internal intermediate step or every receipt must be filed down to the smallest detail. It is crucial that the information on the origin, the components of intermediate products and the quantity ratios can be retrieved clearly, completely and verifiably at any time. Companies are called upon to align their documentation practices in such a way that they can work both legally compliant and efficiently.

With regard to EUDR traceability, the creation and further processing of collective batches and intermediate products does not represent an obstacle in principle, provided that suitable systems are used for recording, transfer and control. The central aim should be to ensure transparency even in the case of several successive processing steps - through targeted process design and division of responsibilities. With a structured, risk-based approach and modern traceability systems, companies are able to both comply with regulatory requirements and leverage internal efficiency potential.

FAQ

Intermediate products are all products that are created during the processing of an EUDR-relevant raw material before they are processed into the end product or placed on the market. Examples: Cocoa mass, flour, wooden boards or refined vegetable oils. These must also be fully documented in terms of origin and quantity.

As long as there is no mixing with other original batches and the material is in the possession of the same company, simple production documentation is sufficient. Detailed traceability and an EUDR-compliant due diligence declaration are only required if the material is resold or mixed with other sources.

Each partial quantity of a collective batch must be clearly and traceably documented with regard to its origin and quantities. Mixtures may be made as long as the breakdown of the farms of origin and their parcel IDs is clear for each partial quantity taken. Digital systems support compliance with this requirement.

Companies should rely on process-oriented, digital systems that structure input, processing and output data and link them in a traceable manner. Employees should also be trained and clear responsibilities established. In this way, all EUDR traceability requirements can be reliably met, even for complex collective batches and intermediate products.